Customer Welfare and Responsibility

Ensuring product and service safety is central to SMC’s commitment to quality and customer satisfaction. Each SMC business maintains rigorous safety standards through documented policies and procedures, implementing strict quality control, risk assessment, and compliance measures to meet and exceed industry benchmarks.

Food and Beverage Safety

SMC’s food and beverage facilities comply fully with government regulations. Farms obtain operational permits from the Department of Agriculture (DA), while poultry and hog processing plants are accredited by the National Meat Inspection Service (NMIS), adhering to strict sanitary and safety standards. These plants undergo regular inspections and periodic audits. The Bureau of Animal Industry (BAI) requires shipping permits for live animal movement, while NMIS mandates permits for poultry and meat product transport as part of disease control measures.

Other food and beverage processing facilities secure and renew licenses from the Food and Drug Administration (FDA) and comply with Good Manufacturing Practices (GMP) to ensure product quality and safety. All products have updated FDA Certificates of Product Registration.

Ingredient Sourcing and Manufacturing Standards

SMC carefully selects and vets all ingredients and additives based on strict quality, functionality, and regulatory compliance standards. Suppliers undergo thorough evaluation, and each ingredient is accompanied by a Certificate of Analysis to confirm it meets specifications.

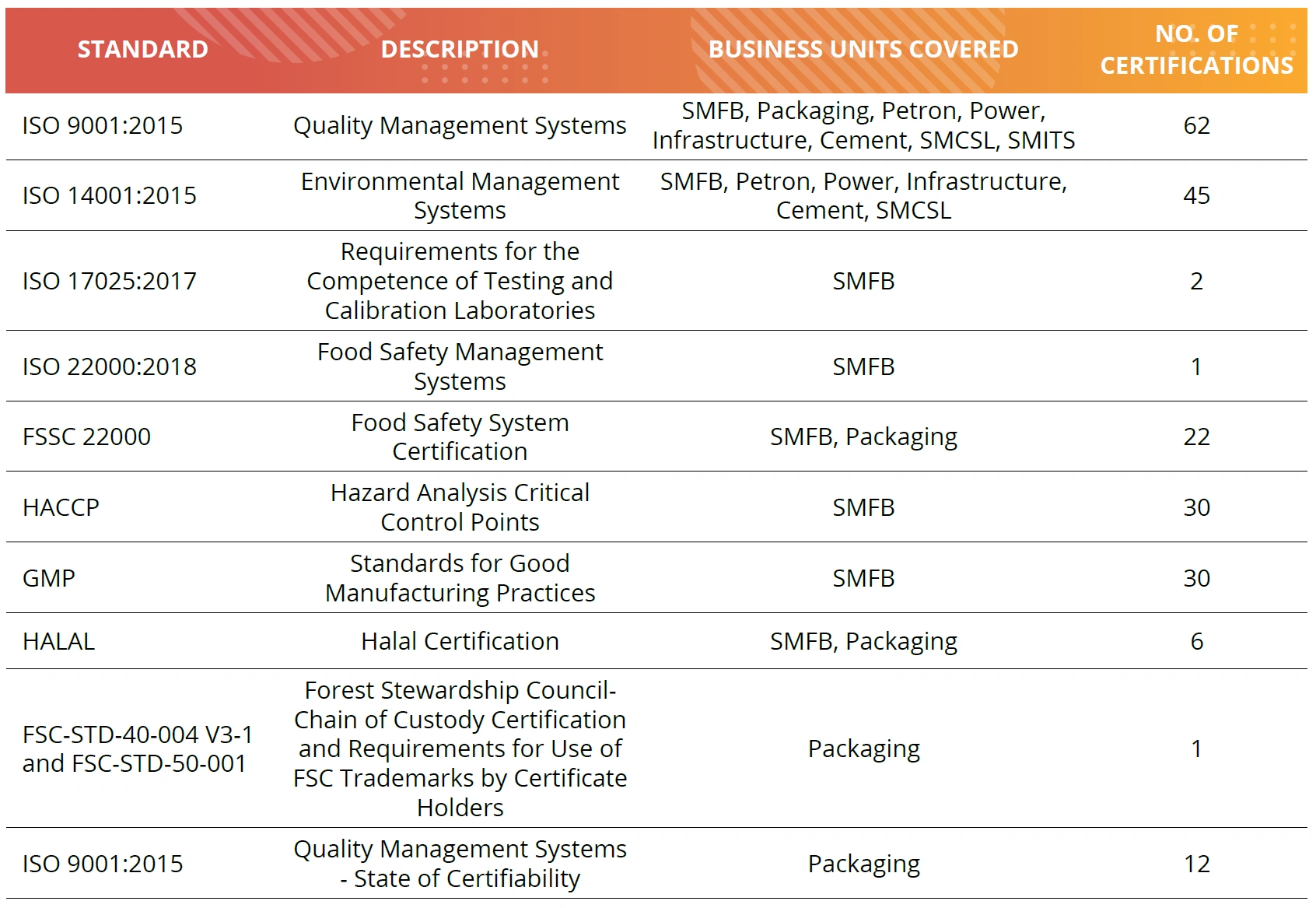

Manufacturing follows ISO standards and Food Safety System Certification (FSSC) protocols, recognized as the highest food safety benchmarks. These certifications enforce traceability systems and require corrective actions when deviations occur, minimizing risks and preventing recurring non-compliance.

Committed to its Core Purpose of “Nourishing People, Nurturing Life,” San Miguel Foods updated three policies related to quality and safety in 2023-2024.

https://www.sanmiguelfoods.com/about-us/corporate-governance

Food safety and quality

Applies to all products - from fresh chicken and meats, processed and ready-toeat foods, plant-based products, flour, dairy, spreads, and coffee to animal and aquatic feeds, pet food and veterinary products

Implements strict internal systems throughout the supply chain

Complies with all regulatory and international food safety standards

Adheres to customer-specific quality requirements

Cultivates a culture of excellence and accountability among employees, suppliers, and partners

Empowers people through training programs like the Quality Assurance School

Fosters a healthy work environment that drives continuous improvement

Antibiotic use for poultry

Emphasizes that good nutrition, biosecurity, proper husbandry, and comfortable housing are key factors in raising healthy and productive animals.

Antibiotics are unnecessary for producing wholesome poultry products at the lowest cost

Allows that prudent use of antibiotics may occasionally be required strictly for treatment purposes, but only when a positive clinical outcome is possible and limited to the necessary duration

Strictly prohibits the use of antibiotics classified by the World Health Organization (WHO) as “Highest Priority Critically Important” for human medicine

Only uses antibiotics approved by the DA-BAI and solely under the supervision of licensed veterinarians

Strictly adheres to government-mandated withdrawal periods to prevent drug residues in poultry meat

Nutrition

Commits to enhancing the nutritional quality of its products prioritizing consumer health and well-being

Aims to be a leader in nutrition by promoting transparency, responsible sourcing, and providing balanced, affordable, and accessible food choices

Sets specific targets for reducing sodium, sugar, total fat, and trans fats while increasing beneficial ingredients and fortification

Follows a phased reduction strategy for sodium and sugar while eliminating trans fats and limiting artificial sweeteners

Aims to expand its healthier product portfolio by incorporating functional ingredients and fortifying products with essential nutrients

Prioritizes consumer education along with clear and transparent labeling to communicate health benefits

Strengthens partnerships with industry experts and regulatory bodies to ensure continuous progress and alignment with evolving health trends and consumer needs

By meeting the highest safety standards, enforcing strict compliance with policies, and ensuring full traceability, San Miguel gives customers the confidence to use, consume, and rely on every product and service we provide.

Transparent Labeling

SMC labels its products in full compliance with FDA Administrative Order No. 2014- 0030, which governs prepackaged food labeling in the Philippines. Labels clearly identify allergens, whether directly present or introduced during production, and include essential nutritional information (e.g., calorie content, macronutrient and micronutrient composition, and serving size). This transparency helps consumers make informed choices, reducing food waste and promoting well-being.

Sustainable Packaging and Disposal

SMC complies with the Extended Producer Responsibility (EPR) Law, using disposal labels (e.g., tidyman, recycling logos) to guide consumers on proper waste management. The businesses covered by and compliant with the EPR Law are SMFB, Petron and the Cement companies.

The Company is transitioning to eco-labels based on Philippine National Standards for Ecolabeling, aligned with the International Resin Identification System.

SMC’s packaging business, serving multiple industries, prioritizes safety with eight FSSC 22000-certified plants. Its corrugated carton plant in Mindanao holds FSC Chain of Custody Certification, verifying responsible sourcing of wood, paper, and forest products from legal, ethical, and sustainable suppliers, reducing the risk of illegal logging or deforestation.

From call centers to social media, we use real-time tools to hear our customers—and respond with care and speed.

Corporate Safety and Product Stewardship

At Petron, the Corporate Safety group fosters a strong safety culture through a Corporate Safety Management System, covering operations from refineries and terminals to the retail network. These facilities follow strict safety protocols, including third-partycertified management systems, regular safety orientations, and enhanced security measures to protect visitors and personnel. Petron also prioritizes product stewardship by adhering to the Globally Harmonized System (GHS) for chemical classification and labeling, ensuring accurate hazard communication. All fuels, lubricants, and greases comply with Department of Energy (DOE) labeling guidelines and meet industry standards (API, SAE, ISO) for viscosity grade and service levels. Each product includes a comprehensive Material Safety Data Sheet (MSDS) with essential handling and safety procedures. Petron further enhances safety through GHS training for personnel involved in purchasing, forwarding, customs clearing, warehousing, emergency response, and chemical handling, promoting a safe and compliant workplace.

Similarly, Cement provides the necessary product information to ensure customer safety. This is accomplished through readily available Product Data Sheets (PDS) and Safety Data Sheets (SDS) distributed by the Sales and Marketing Team. In instances when specific customers require it, LEED forms are provided. The packaging and labeling of cement are regulated by the DTIBPS under PNS 07:2018 and PNS 63:2019 standards. According to these regulations, cement bags must contain essential information such as the manufacturer’s name and address, type and classification of cement, product specification and application, trade name, trademark, net mass, batch number, manufacturing date, and the phrase “Product of the Philippines.” The labels also include color bands corresponding to the cement type to help ensure clear identification and safe handling by consumers.

Tollway Safety

SMC Infrastructure ensures tollway safety by adhering to the Toll Regulatory Board (TRB) guidelines for the establishment, operation, and maintenance of toll facilities. Regular inspections guarantee safe road conditions, clear signage, and effective hazard mitigation. Tollway personnel are trained to handle accidents, grass fires, floods, hostile incidents, and other disruptions, following strict emergency response protocols.

Customer Feedback and Continuous Improvement

SMC prioritizes customer feedback to enhance services and maintain satisfaction. The Customer Care Hotline (+632 8632-2000), managed by SMITS subsidiary Prosync, is complemented by individual business unit hotlines. Some units use CRM software to log cases, assign resolutions, and follow up, while others conduct Customer Satisfaction Surveys to gather insights and drive improvements.

SMC stays connected through active Facebook pages and listed contact details on company websites. Social media monitoring tools help track and respond to customer feedback, ensuring concerns are addressed promptly.

By combining comprehensive safety programs, strict compliance, and continuous improvement, SMC upholds its commitment to delivering quality products and maintaining customer confidence.

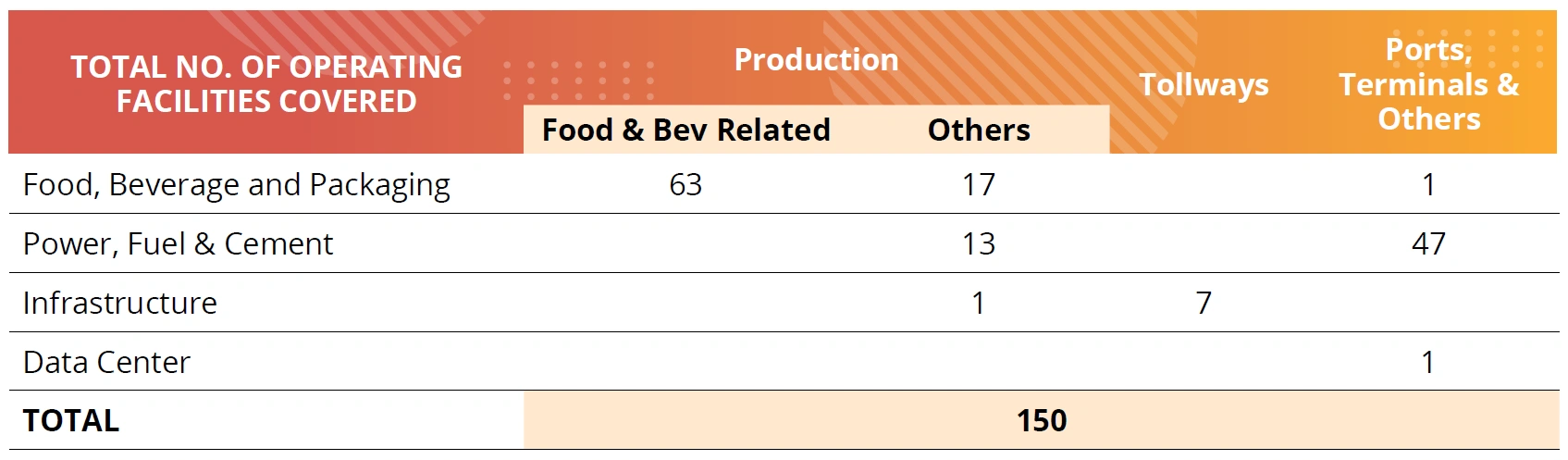

The following tables tally the various international and local standards that our businesses are certified for. A complete list of accredited facilities is available in the Appendices.

Our certifications are not just credentials; they are our promise to customers that every product is made with care, meets global standards, and puts their safety first.