Resource Management

While every company faces unique resource challenges, San Miguel consistently strives to be at the forefront of responsible resource use. We consider natural capital—our forests, water, land, and ecosystems—a vital part of how we operate. By managing these resources efficiently and sustainably, we aim to support long-term benefits for our country and the communities we serve.

In 2020, San Miguel launched the River Rehabilitation program to restore and revive river systems in Metro Manila. Buoyed by the initial results, we expanded the program to adjacent provinces of the metropolis. As of this reporting period, dredging and clean-up activities have been completed in the provinces of Bulacan, Laguna and Pampanga. In Bulacan alone, the program removed 4,134,880 cubic meters of silt and solid waste. In Pampanga, 694,372 cubic meters were cleared from major tributaries, while in Laguna, 417,044 cubic meters and 87,899 cubic meters of waste were removed from the rivers of San Pedro and Biñan, respectively.

These efforts complement our Water for All program by addressing “blue water”—the visible, tangible water that feeds into the groundwater system and overall water cycle. To protect “green water”—the moisture stored in vegetation and soil that returns to the atmosphere through evaporation and transpiration—we launched Project 747, our large-scale reforestation initiative. The project aims to plant seven million trees across four thousand hectares of deforested lands in seven vulnerable provinces in the Philippines. As of this report, over 6.5 million trees have been planted. These reforested areas play a crucial role in sustaining rainfall patterns in regions where water sources are already severely compromised.

We also partnered with the University of the Philippines Los Baños-College of Forestry and Natural Resources to conduct a science-based assessment of carbon sequestration of mangrove areas adopted by Petron under its Puno ng Buhay reforestation program. The partnership will initially focus on mangrove sites in three provinces, covering a total area of 55 hectares.

Since its launch in 2016, San Miguel’s Water for All program has saved a total of 48,981,524 cubic meters of freshwater— equivalent to the monthly water consumption of 1.6 million Filipino households. Through initiatives such as wastewater recycling and rainwater harvesting, we remain deeply committed to conserving water resources. We also recognize the role of economic drivers in shaping the water cycle and ensure that our operations support responsible water use and long-term regeneration.

NCC’s ongoing reforestation programs continue to restore local ecosystems where our operations are located while supporting our broader emissions reduction efforts. In 2024, an additional 4.78 hectares were reforested with 1,880 assorted fruit-bearing trees, in partnership with local communities and LGUs.

To date, NCC has planted a total of 107,000 seedlings across 217.59 hectares in conjunction with the government’s National Greening Program (NGP) and Mining Forest Program (MFP).

Improving energy performance starts with building the right systems and capabilities. At San Miguel, we see energy efficiency as the first step in our Net Zero by 2050 goal. To support this, our businesses have begun integrating energy management systems (EnMS) following the ISO 50001:2018 Energy Management Standard.

In 2024, 392 participants from Petron, Cement, Food and Beverage, Properties, Packaging and OMM groups have completed a two-day training program focused on implementing ISObased EnMS. The program focused on integrating EnMS into existing workflows and complying with the Energy Efficiency and Conservation Act of 2019 (RA 11285). The training was designed to be flexible, taking into account the different ways our businesses operate. This allowed us to apply a common system that works across the Company while still fitting the specific needs of each team.

SMC has long recognized that environmental challenges require a whole-of-business response. Our programs are built on a systemsbased, preventive approach— focused on reducing the use of materials, water, and energy, minimizing environmental impact, and safeguarding the health and well-being of the communities where we operate.

A. Energy Management

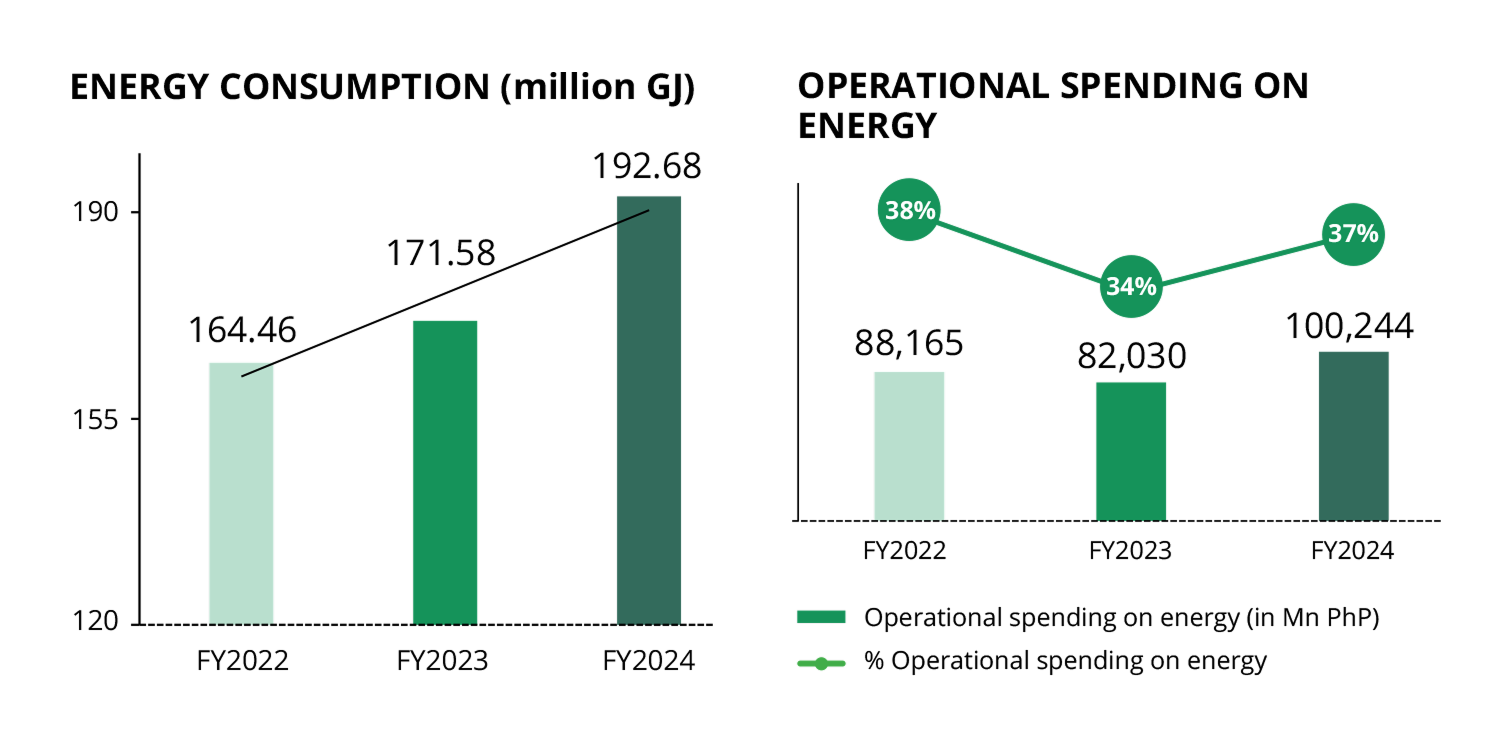

In 2024, San Miguel Corporation consumed 192.7 million GJ of energy—an increase of 12.3% compared to the previous year. The rise was primarily driven by a 30.3% increase in electricity generation by our Power business, reflecting growing demand from electric utilities and industrial customers. This is in line with International Energy Agency’s 2025 Global Energy Review report, showing more than 7% increase in Southeast Asia electricity demand in 2024 compared with about 4% in 2023.

Non-renewable energy consumption increased by 19.4% overall, coming from an increase of 176.5% for natural gas and 5.1% for coal. At the same time, renewable energy use also grew by 31.7%, supported by the expansion of hydropower capacities, the integration of solar power, and the deployment of battery energy storage systems— all part of our Net Zero transition roadmap.

Electricity consumption across our Company increased by 0.5% in 2024. The increase in electricity consumption was largely driven by our Food and Beverage business, which accounted for 32.8% of our total electricity consumption. Food reported a 15% rise in electricity use—due to extended operating hours, and the addition of newly acquired and constructed facilities, which delivered a 17% increase in production volume.

Total net energy consumption increased by an average of 8.2% year-over-year, reflecting the country’s level of economic activity as the pace of growth exceeded earlier projections, leading to higher-than-expected energy demand across key sectors.

In 2024, our total operational spending on energy increased by 10.9%, largely driven by a 39.4% increase from SMGP to meet the country’s growing energy demand. The year marked the hottest on record globally, with extreme temperatures driving up cooling requirements across commercial and industrial sectors. Global cooling degree days (a measure of how hot the temperature is within a given period) were 6% higher than in 2023 and 20% above the 2000-2020 average, underscoring the intensifying impacts of climate change on energy systems.

The rising adoption of electrified vehicles, which accounted for 4% of national vehicle sales following the implementation of zero import duties, further added to grid demand. At the same time, newly operational assets—including the Mariveles power plant and BESS sites—were incorporated into our energy reporting this year.

In 2024, we deployed 390 MWh of BESS capacity to help stabilize our national grid and enable higher renewable integration. We also supported the energization of a 184-circuit-kilometer High Voltage Direct Current submarine cable, with a transfer capacity of 450 MW, interconnecting Luzon, Visayas, and Mindanao grids.

As the country’s leading power supplier, we remain focused on building a more resilient and flexible energy system—one that enables a fully connected Philippines and ensures that the benefits of electrification are shared by all Filipinos.

In 2024, rising demand from key sectors—notably power, transport, and industry—led to a 28.7% increase in energy consumption by our Power business. In contrast, energy consumption declined by 10.3% at Petron and by 5.6% on average across our Cement businesses. Energy use among other business units remained at about 6% of total consumption, but increased by 5.6% versus 2023.

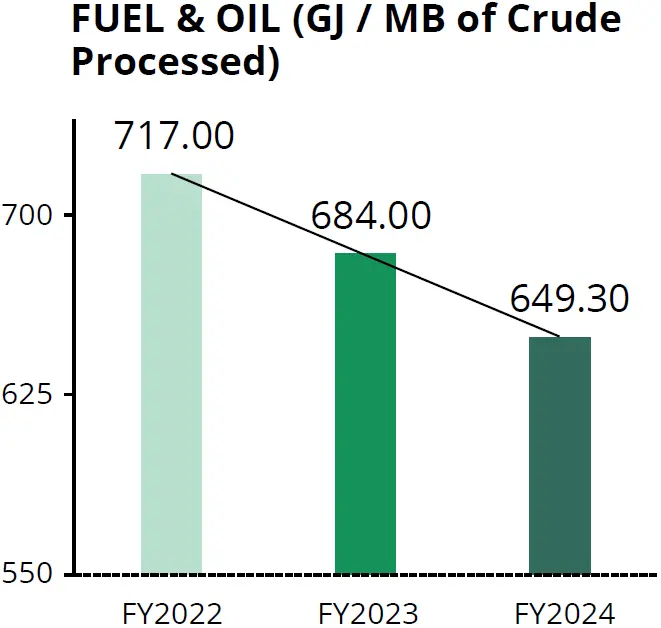

Petron’s average energy intensity decreased by 4.8% year-overyear, driven by sustained efforts in managing its energy use and implementing energy efficiency measures in their refinery operations. In 2024, energy reduction initiatives reached an 85.4% implementation rate through various programs such as: i) Fuel, Steam, Water & Power Balances; ii) Fuel, Utilities, Loss & Conservation Activities; and iii) Fuel Insights & Recommendations for Efficiency. These efforts resulted in savings of 9.5 million liters of oil equivalent, while the Empower Change (Water + Electricity Conservation) program reduced electricity consumption by 658.7 MWh. The energy management programs at Petron Bataan Refinery focus on optimizing resource efficiency, promoting collaboration, and fostering conservation awareness. They provide usage projections for fuel, steam, water, and power to guide operations and analyze variances for better performance. The programs also enhance collaboration by keeping the refinery informed about energy initiatives, addressing implementation challenges, and encouraging feedback. Additionally, they drive actions for

Across our major businesses, we reduced energy intensity in 2024— despite higher production and sustained economic activity.

efficient furnace operations and use visual dashboards to raise awareness and promote shared responsibility for water and electricity conservation.

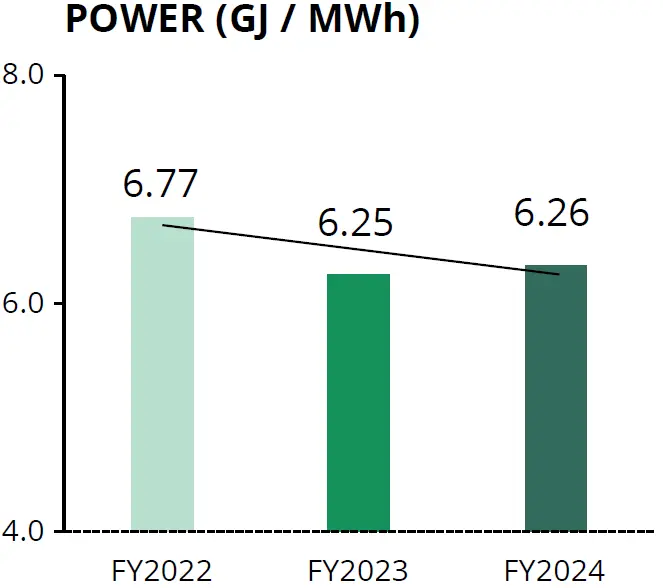

Our Power business reduced its average energy intensity by 4.3% year-over-year, supported by proactive efficiency measures and demand management strategies. SMGP worked closely with key utility customers and responded in real time to price fluctuations in the electricity spot market, ensuring that excess production capacity was aligned with load profile requirements.

Energy intensity of our Cement business increased by 9.5% in 2023, as NCC started to operate a third line alongside its two 57- year old lines. In 2024, the third line’s performance was optimized and became the main production line, allowing stoppage of the two older lines. As a result, energy intensity was 9.4% below 2023 level and slightly lower than 2022. The following efficiency initiatives complemented this change:

Eagle Cement commissioned a waste heat recovery plant that generated 75,931 MWh of energy and installed a hot gas recovery system that saved 15.5 million liters of diesel. These efforts led to a 12.7% reduction in electricity consumption and a 7.4% reduction in fuel use.

Northern Cement’s third line resulted in electricity savings of 3,003 MWh and diesel savings of 2.2 million liters, achieved through the recovery of hot gas from the kiln for use in the vertical roller mills.

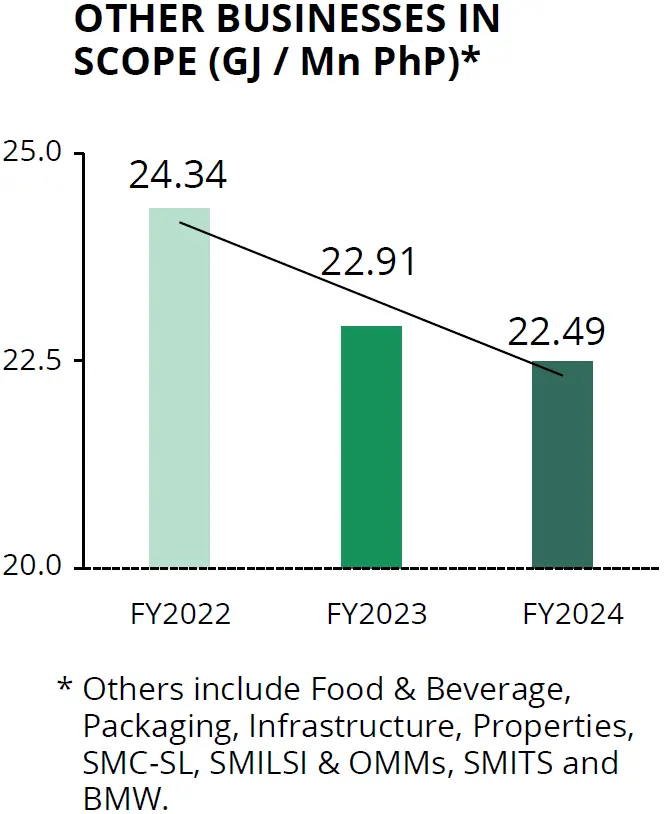

Other business units implemented a range of energy-saving initiatives that collectively contributed to a 3.9% reduction in average yearover- year intensity across the organization.

Despite substantial growth in production volume, our Food business managed to control its energy use—saving 0.7 million liters of oil equivalent and 5,038 MWh of electricity in 2024. The Beverage Division reduced consumption by 16.1 million liters of oil equivalent and 13,768 MWh of electricity. GSMI contributed significantly through ongoing efficiency programs, including a transition to LED lighting and replacement of outdated air conditioning units with inverterequipped, energy-efficient models. Additional measures included the installation of solar panels at one facility, increased use of solarpowered perimeter lighting, and continued optimization of GSMI’s biogas generation facility.

Across our brewery operations, we also implemented systemwide efficiency upgrades in the following areas:

Sequencing Batch Reactor systems

Dewatering equipment including auxiliary pumps

Compressors for dry air, NH3, CO2, air, water, and bagasse

Chilled water and diffuser systems

Motors and drive gears

The Food group reduced coal consumption for boilers by 180,000 MT in 2024 and implemented a range of energysaving measures, including using condensate return as a preheater for boiler feed water, converting diesel-powered forklifts to electricpowered units, and installing solar-powered lighting across warehouses and plant premises.

SMYPC strengthened its energy management efforts by training 36 personnel from 14 facilities—including engineering heads, engineering supervisors, maintenance and utilities teams, department heads, technical managers, transportation and warehouse planners, safety, and environment and production staff engineer—through a twoday EnMS implementation workshop held in September 2024. SMYPC adopted the core elements of EnMS and launched an annual recognition program for facilities that achieved energy use reductions through process optimization, adoption of energy-efficient motors and compressors, and installation of solar PV systems and solar street lamps. As a result, participating sites saved a total of 7,349 MWh of energy through successful implementation of the EnMS.

We are building a culture of energy responsibility— training teams, optimizing systems, and embedding efficiency across operations.

B. Water Management

In 2024, SMC continued to enhance its water management initiatives, prioritizing efficiency and minimizing wastage across its operations. The Group’s two largest water consumption categories are utility water, used for cooling and cleaning processes, and freshwater for food and beverage manufacturing. Additionally, water is utilized for sanitation, irrigation, and domestic purposes.

Of SMC’s total water withdrawal, 93% is accounted for by Power, which uses 99.9% seawater. The seawater passes through condensers or cooling systems, where it absorbs heat from the steam used in power generation. After serving its cooling function, the seawater, now only slightl ywarmer, is safely returned to the ocean in accordance with environmental standards. In addition, Petron’s desalination plant enables the refinery to use seawater for its operations while avoiding rust and calcification. As a result, seawater constitutes 96.7% of the Group’s total water usage, amounting to approximately 3.5 million ML.

SMC is also actively developing rainwater harvesting programs to supplement scarce freshwater resources. The NCC facility in Pangasinan has successfully implemented this program, achieving a 93.8% reduction in freshwater usage, with a goal of eventually reaching zero freshwater consumption. Several other facilities have introduced smaller-scale rainwater collection systems, enabling the use of harvested rainwater for ground maintenance, irrigation and some domestic sanitary applications.

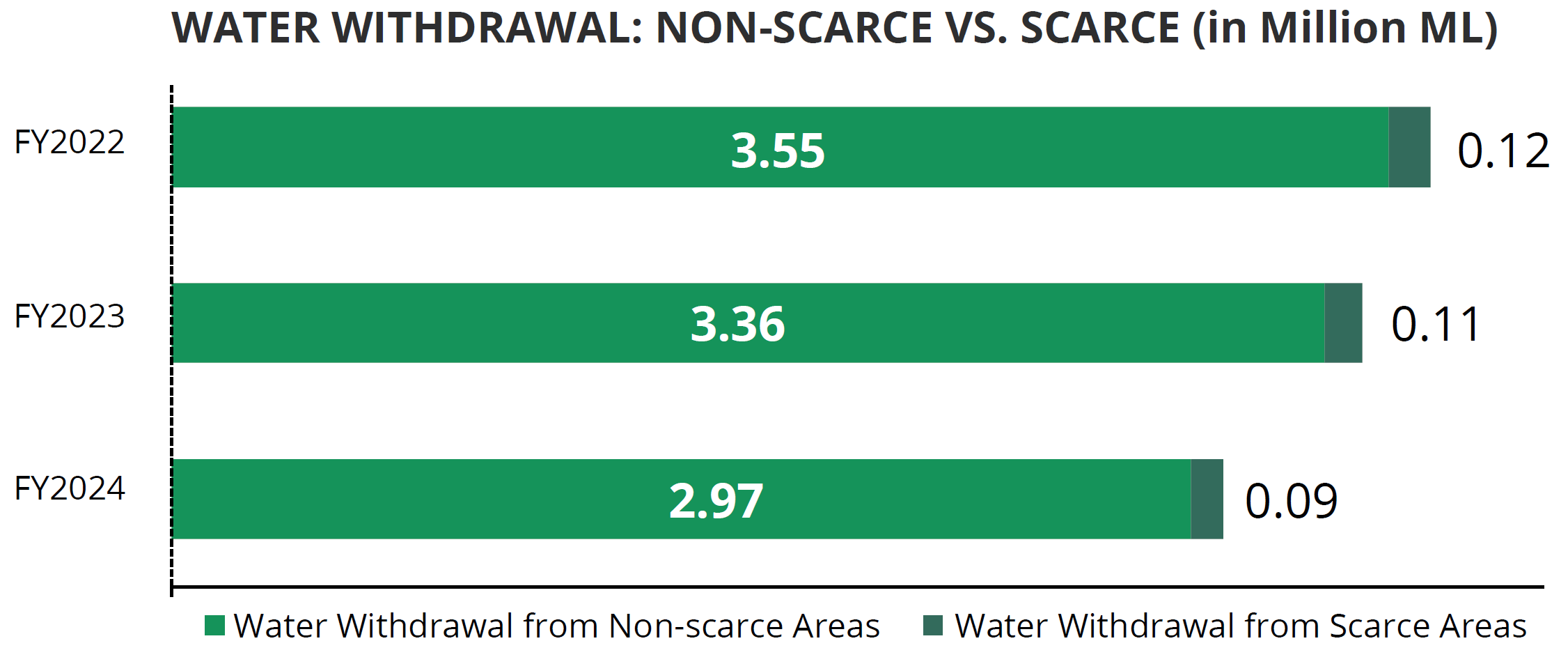

While groundwater, surface water, and third-party water account for only 3.3% of SMC’s total water usage, the Company continues to implement multiple initiatives to optimize its consumption.

These include:

Employee awareness campaigns across all SMC facilities, encouraging staff to report malfunctioning devices and be mindful of water usage.

The installation of pressureregulating valves to maintain water pressure at or below 40 psi, preventing unnecessary water loss.

The deployment of sand filters and water softening systems at various plants to enable the reuse of maintenance water for sanitation purposes.

A food plant conducting cleaning cycle optimization studies to reduce water consumption without compromising food safety.

The use of water treatment systems that allow effluent water to be recycled for road dust suppression and other non-sensitive applications.

For domestic uses, SMC continues to install water-efficient plumbing and sanitary fixtures, including:

Aerators and flow restrictors on taps to reduce flow rates.

Waterless and hybrid urinals, which reuse handwashing water for flushing.

Half-flush systems and improved flush-o-meters to reduce water use per flush.

When properly implemented, these fixtures can reduce water consumption by up to 30%, depending on the facility’s baseline usage.

Through these comprehensive measures, SMC demonstrates its unwavering commitment to the responsible and efficient use of natural resources, ensuring that no drop of water is wasted.