Climate Change Action

Climate change is no longer a distant threat—it is a crisis unfolding before our eyes, impacting communities, economies, and ecosystems worldwide. As a company committed to sustainability and operating in industries vital to the Philippine economy, we recognize that the country faces severe climate risks. Extreme weather events, rising temperatures, and shifting agricultural conditions present urgent challenges. At the same time, we are committed to uplifting our people from poverty by expanding access to essential services and creating economic opportunities that drive inclusive economic growth.

The outcomes of the United Nations Climate Change Conference (COP29) have reinforced the need for decisive action to mitigate climate risks and adapt to their impacts. These decisions not only shape international climate policy but also influence the strategies we must adopt to strengthen our operations, stakeholders, and communities for the long term.

One of COP29’s key takeaways was establishing a new climate finance goal, with developed nations pledging $300 billion annually until 2035 to support climate action in developing countries. While this triples the previous $100 billion pledge, it remains far below the estimated $1.3 trillion per year that some experts argue is necessary. For the Philippines, which is highly vulnerable to climate change, securing adequate climate finance is critical for resilience and sustainable development.

Another milestone was finalizing global carbon market rules under Article 6 of the Paris Agreement. This framework will drive investments in low-carbon technologies and emissionsreduction projects through carbon credit trading. However, regulatory uncertainty and volatile pricing may pose short-term challenges. As a company, we recognize both the opportunities and risks and see the value in integrating market-based climate solutions into our decarbonization strategy.

COP29 also emphasized the urgency of strengthening Nationally Determined Contributions (NDCs), requiring all countries to submit updated climate action plans by February 2025. The conference called for more ambitious, transparent, and science-based commitments, underscoring that private sector involvement is essential in achieving national and global climate goals. While the Philippines has yet to submit its updated NDC, we remain committed to working closely with government to align our contributions with emission reduction targets and climate adaptation initiatives.

COP29 emphasized that private sector involvement is essential in achieving national and global climate goals – and we are committed to doing our part.

Despite these advancements, COP29 fell short on bold action regarding fossil fuels, energy transition, and emissions reductions, with stalled negotiations and a lack of new commitments. The gap between developed and developing nations remains wide, highlighting the need for more aggressive and innovative climate action. As a company operating in industries closely associated with climate change, we must proactively implement solutions that reduce our environmental footprint and drive sustainability.

A. Greenhouse Gas (GHG) Emissions

Since publishing our first Sustainability Report in 2022

San Miguel Corporation has committed to building a datadriven approach to emissions accounting, grounded in transparency and aligned with international standards.

Our journey began with a clear goal: measure, manage, and reduce our GHG emissions while aligning our operations with the scale and urgency of climate action. But as our business continues to evolve—with new operations, acquisitions, and national-scale infrastructure projects—we have also evolved how we track progress.

In 2023, we expanded our reporting scope to include two cement businesses and a feed mill plant. In 2024, we incorporated San Miguel Aerocity Inc. (SMAI), developer of the New Manila International Airport, and marked SMGP’s becoming the largest power generation provider in the Philippines.

These changes have a measurable impact. Total GHG emissions increased due to expanded coverage and operational growth. However, by recalculating our 2022 baseline to align with the scope of subsequent years, we can now track performance with consistency and integrity—yearover-year, across sectors, and through transformation.

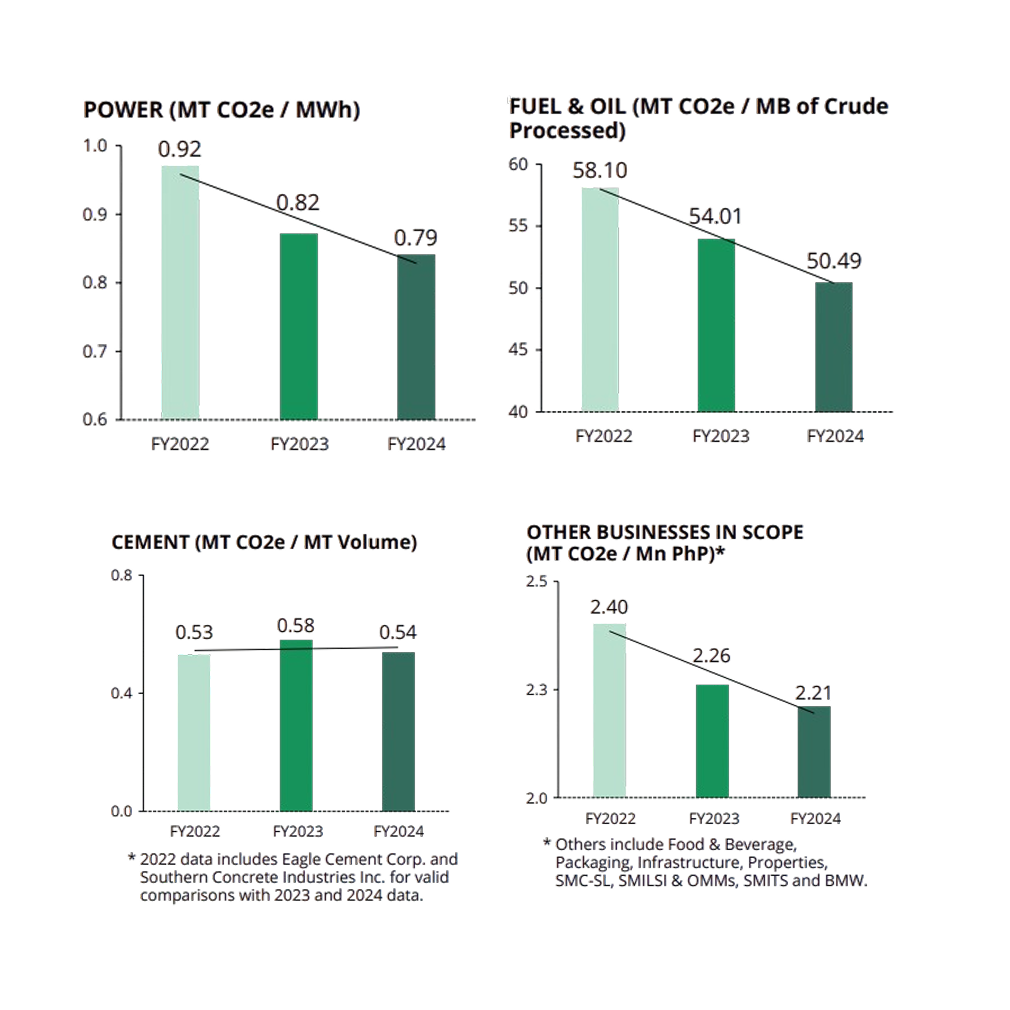

Across SMC’s major businesses, GHG emission intensity has generally improved from 2022 to 2024, reflecting continued gains in operational efficiency.

We use GHG emission intensity as a core metric: emissions per unit of output. This allows us to account for scale while measuring efficiency improvements over time.

Across SMC’s major businesses, GHG emission intensity has generally improved from 2022 to 2024, reflecting continued gains in operational efficiency. Despite business growth and expanded operations, our Company mostly sustained a downward trend in GHG intensity through focused efforts and targeted initiatives.

Our journey began with a clear goal: measure, manage, and reduce our GHG emissions, while aligning our operations with the scale and urgency of climate action.

Petron, our fuel and oil business, has driven significant progress toward reducing our emissions intensity. With an initial target set in 2018, to reduce GHG emission intensity by 25%, the Petron Bataan Refinery exceeded expectations, achieving a 39.3% reduction in 2024 against the baseline. Over the last three years, the integrated GHG emission intensity of the Refinery and the co-generation facility has dropped 6.8% year-over-year. Central to these efforts was the installation of two flare gas recovery units (FGRUs), significantly decreasing the volume of gas burned and reducing flaring and downtime in refinery operations. Since their commissioning in 2021, these units have recovered a total of 110.93 thousand barrels of crude equivalent, avoiding approximately 53,274 MT CO2e in emissions. Further improvements to the fuel gas network, completed in 2024, allowed all process heaters to function optimally. Additionally, the decommissioning of the Direct-Fired Air Heater (DFAH)—previously used as supplementary heating during catalytic cracking—resulted in fuel gas savings of 5.7 million standard cubic meters (scm³), equivalent to 12,889 MT CO2e of avoided emissions.

Petron has implemented multiple complementary initiatives aimed at advancing and sustaining emission reductions across its operations. These efforts include: (i) optimizing boiler systems; (ii) transitioning to more energyefficient lighting and cooling systems in offices and operational areas; (iii) expanding local renewable energy generation for streetlighting; (iv) conducting regular preheat exchanger cleaning; and (v) adopting an energy management system aligned with ISO 50001 across refinery and terminal operations. In 2024, 58 engineering, environment, and maintenance personnel from Petron’s refinery and terminal operations participated in comprehensive training workshops to effectively implement the ISO 50001:2018 standard. Following these workshops, Petron initiated gap analyses to systematically embed energy management system principles into daily operational processes, targeting ISO 50001 certification. Concurrently, evaluations are ongoing for installing grid-connected rooftop solar photovoltaic (PV) systems designed to sustainably power administrative and operational buildings. Collectively, these consistent and systematic initiatives enabled Petron to achieve a significant reduction of 34,339.76 MT CO2e in 2024.

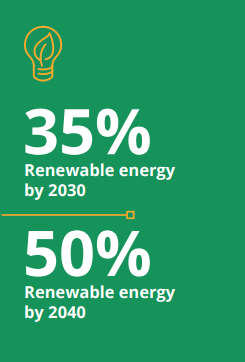

Our Power business, accounting for 61% of SMC’s total GHG emissions in 2024, has embarked on a comprehensive energy transition roadmap aimed at achieving our ambitious Net Zero by 2050 goal. Several significant projects are already underway to advance this vision, simultaneously supporting the Philippines’ national objective to increase the share of renewable energy to 35% of the total energy mix by 2030, and 50% by 2040. In 2024, we initiated expansion in our renewable energy portfolio, starting with upgrading the capacity of Angat Hydro Power Plant from its current 218 MW generating capacity to 254.58 MW. Concurrently, SMC Global Light & Power Corporation, the dedicated unit for renewable energy projects, partnered with Citicore Renewable Energy Corporation to jointly develop and operate a 221 MW solar power plant in Mariveles, Bataan. The collaboration commenced in 2024, with the plant targeted to become fully operational by 2026. These strategic renewable energy projects highlight our continued commitment to decarbonization and mark significant progress toward our goal of achieving Net Zero emissions.

Supporting this transition is our pioneering Battery Energy Storage System (BESS) initiative. San Miguel Global Power, through its subsidiaries, currently operates 390 MWh out of the 1,000 MWh BESS capacity, strategically deployed nationwide. These BESS units provide critical ancillary services to the National Grid Corporation of the Philippines (NGCP), ensuring backup power supply for enhanced grid stability and reliability. Furthermore, the BESS units function as stored energy sources for distribution utilities and industrial customers, particularly during periods of load shifting, peak shaving, or voltage correction.

Our Cement business increased its total output by 4% in 2024, contributing approximately 36% of the Philippines’ overall cement production. This growth was achieved while simultaneously reducing GHG emission intensity compared to the previous year, driven by the strategic shift to more energy-efficient production lines and integrating an energy management system aligned with ISO 50001 standards across its operations.

In 2024, Eagle Cement Corporation (ECC) began preparations for ISO 50001 certification and successfully met all compliance requirements within the year. ECC also continued to implement several initiatives aimed at reducing fuel consumption and avoiding additional GHG emissions. Key contributors to these efforts were a waste heat recovery system, the efficient use of hot gas in the vertical roller mill and inclusion of supplementary cementitious materials, such as fly ash, as clinker substitutes, all while maintaining high product quality and performance standards. Over the past two years, ECC’s focused sustainability efforts have led to the avoidance of 3.3 million MT CO2e emissions. Collectively, these initiatives delivered a 1.4% decrease in GHG emission intensity in 2024.

Northern Cement Corp. (NCC) achieved significant reductions in GHG emissions in 2024, with Scope 1 and Scope 2 decreasing by 14.9% and 22.3% in emissions, respectively, leading to a substantial reduction in GHG emission intensity of 17.1%. To further embed energy efficiency practices, NCC organized a comprehensive two-day training workshop on implementing an energy management system aligned with the ISO 50001:2018 standard. This training was attended by 31 supervisors and engineers representing diverse departments across its operations. Recognizing the importance of continuously integrating these practices into its operational framework, NCC plans to conduct a second training session in the first quarter of 2025, reinforcing its ongoing commitment to sustainable improvement and energy management.

Southern Concrete Industries Inc. (SCII) implemented targeted initiatives aimed at reducing power consumption and lower GHG emissions. These initiatives include: (i) Project E.V.E. (Eradicate Vampire Energy), which targets energy waste reduction; (ii) isolation of compressed air utilization in the Packhouse and suspension of its firstshift operations; (iii) controlled operations of perimeter lighting; and (iv) participation of 23 engineering, maintenance and operation personnel in a twoday workshop focused on the implementation of an energy management system aligned with ISO 50001 standards. Through these strategic measures, SCII achieved substantial reductions in its 2024 emissions, lowering Scope 1 emissions by 9% and Scope 2 emissions by 12%, resulting in an overall GHG emission intensity reduction of 19%.

Our other businesses recorded an average annual increase of 2.5% in GHG emissions, substantially lower than the 6.9% increase in revenue for these businesses. While accounting for 41.8% of Company-wide sales revenue in 2024, total GHG emissions contributed only 4.5% to total. GHG emissions intensity for this group of businesses was lower by 4.2% year-over-year.

In addition to energy conservation which is the main initiative for this group of businesses, some units have started to work on establishing an energy management system aligned with ISO 50001 standards, laying the foundation for a structured and systematic approach to reducing emissions across all facilities. As part of this initiative, a comprehensive two-day training workshop was conducted, attended by 244 personnel—including production heads, plant managers, energy managers, energy auditors, and maintenance engineers from the SMFB and Properties business units. Participants will apply the knowledge and strategies gained to their operations, establishing the groundwork for a structured and systematic approach to reducing GHG emissions across the division.

San Miguel continues to grow— but so does our commitment to climate accountability. By maintaining a consistent methodology, investing in operational efficiency, and scaling clean technologies across sectors, we are building the foundation for a lower-carbon future.

We know this is a long-term effort. We also know that emissions performance must be transparent, measurable, and rooted in realworld business progress. This report reflects not just where we are—but where we are going.

B. Scope 3 GHG Emissions

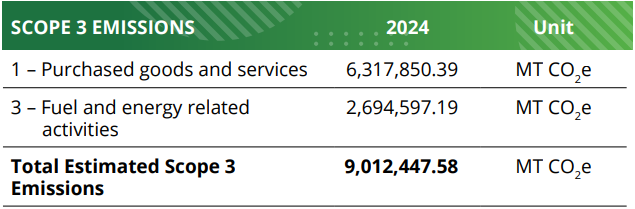

SMC began identifying its Scope 3 GHG boundaries in 2023, using the GHG Protocol Scope 3 Standard as a guide. Each business underwent a screening process to determine their most relevant and material Scope 3 categories out of the 15 available. The assessment was based on five key criteria: size, influence, risk, stakeholder importance, and outsourced activities. Sector-specific guidance was also used to identify significant categories. Across the businesses, seven were found to be common and material at the consolidated level.

We know this is a long-term effort. We also know that emissions performance must be transparent, measurable, and rooted in real-world business progress.

Each business collected activity data for its identified boundaries using a standardized Scope 3 data collection template. The emission data was then consolidated at the holding level. During the initial assessment, five categories were found to have high levels of uncertainty, minimal coverage, or a significant risk of double counting. For this report, we are thus disclosing data from only two of the remaining two categories, namely: Categories 1 and 3.

Category 1

Category 1 covers cradle-to-gate emissions related to our purchased goods and services. To calculate Scope 3 emissions, we reached out to our suppliers to determine whether they could provide product-specific emissions data for purchased items. Some suppliers were able to share product-level GHG inventory data, which we incorporated into our calculations.

Some of our contracted feed mills and poultry processing plants calculate their Scope 1 and 2 GHG emissions, so we provided a standardized data template for their submission.

For items where suppliers could not provide this information, we used the spend-based methodology to estimate emissions. Emission factors were sourced from the US Environmental Protection Agency’s (EPA) Supply Chain Greenhouse Gas Emission Factors (2024), and the North American Industry Classification System (NAICS) was used to classify purchased and capital goods. Total spend, initially recorded in PHP, was converted to 2022 USD and multiplied by the appropriate emission factor to estimate emissions. Our Category 1 emissions cover the purchase of crude oil, agricultural commodities such as corn, wheat, soybean meal, meat and dairy materials, contracted poultry farms, feed mills and processing plants and other raw materials used by our businesses. While we successfully collected data on our major materials, our data collection remains incomplete due to challenges in obtaining comprehensive information, particularly from local suppliers, and having reference factors more attuned to the nature of materials available in the region.

Category 3

To calculate our Category 3 emissions, we applied the averagedata methodology. Well-to-tank emission factors for various fuels were sourced from the UK Government GHG Conversion Factors for Company Reporting (2023). By inputting our 2024 fuel usage, we multiplied it by the appropriate emission factor to estimate emissions.

The data collected here carries some uncertainty due to the nature of our emission factor source. We aim to obtain more localized emission factor datasets to ensure greater relevance to SMC’s operations.

In this initial assessment of SMC’s total Scope 3 emissions, we are estimating approximately 9 million MT CO2e of emissions based on the collected data. However, due to challenges in data collection and the limitations of our emission factor sources, we acknowledge that this amount is only a fraction of the total. We will continue to refine the number as we enhance our Scope 3 data collection processes.

Moving forward, we aim to improve our Scope 3 data collection process by gathering more comprehensive input data and localized emission factors that better reflect SMC’s operations. We will also strive to expand coverage to the additional categories previously identified.

We’re advancing Scope 3 reporting with greater rigor— standardizing data, working with suppliers, and strengthening our emissions accountability across the value chain.

The table on the top summarizes our Scope 3 GHG emissions for 2024, showing the contributions of each reported category. These figures provide a baseline for ongoing improvements in data collection, accuracy, and completeness as we refine our Scope 3 reporting.

Powering a Sustainability Future

At SMGP, we are driving the transition to a cleaner, more sustainable energy landscape. Our Net Zero Roadmap is built on a clear commitment to renewable energy expansion, emissions reduction, and innovative energy solutions, ensuring a balanced and responsible approach to decarbonization.

Through these strategic initiatives, we are committed to achieving at least 35% renewable energy by 2030 and 50% by 2040, while reducing GHG emissions intensity by 30% by 2030 and 70% by 2040 from 2021 levels. With these investments in clean energy and pioneering of innovative solutions, we are shaping a resilient and sustainable energy future for generations to come.

Our Net Zero Roadmap is built on a clear commitment to renewable energy expansion, emissions reduction, and innovative energy solutions

Our Decarbonization Strategy

1. Expanding Renewable Energy:

- Scaling up hydropower with the expansion of existing plants and the addition of two new hydropower plants between 2030 and 2035,

- Developing solar PV plants in two phases, targeted for 2028 and 2039

2. Integrating Battery Energy Storage Systems (BESS):

- 1,000 MWh BESS fleet in operation

- BESS integration in four coal-fired plants to enhance peak capacity while maintaining carbon footprint

3. Lowering Emissions from Thermal Power Plants:

- Pilot carbon capture technology in a coal-fired plant (97% CO2 capture) with a full rollout by 2030.

- Ammonia co-firing with coal to further cut emissions, targeted for the mid‑2030s

Building a Greener Future

Cement Group's Path to Net Zero

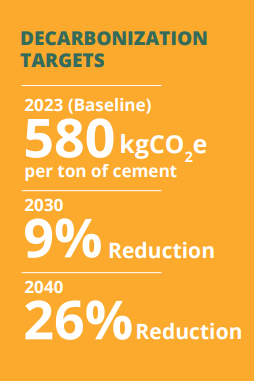

As part of our commitment to a low-carbon future, our Cement Business is implementing a comprehensive GHG emissions intensity reduction strategy. We will leverage raw material substitution, fuel substitution, and renewable energy to drive a significant reduction in carbon emissions while maintaining product excellence.

Key Sustainability Initiatives:

- Raw Material Substitution: Replacing highcarbon raw materials with alternative, eco-friendly inputs to reduce process emissions.

- Fuel Substitution: Transitioning from traditional fossil fuels to lower-carbon or alternative fuels to minimize energyrelated emissions.

- Renewable Energy Integration: Expanding the use of clean energy sources to power cement production and reduce reliance on fossil fuels.

By adopting these sustainable practices, we are aligning with our goal of achieving Net Zero emissions by 2050. Through continuous innovation and responsible production, we are shaping a more sustainable cement industry while contributing to global climate action.

CME Production Roadmap

2025

Planned start of construction of the CME plant.

2027

Projected start of commercial operations, enabling large-scale production of CME.

2029-2030

Petron diesel will incorporate up to 5% CME blend, reaching a production capacity of 74 million liters annually.

Strategic benefits of CME integration

- Carbon Emissions Reduction – CME is a biobased fuel that significantly lowers GHG emissions, contributing to climate change mitigation.

- Enhanced Air Quality – Compared to conventional diesel, CME blends produce fewer pollutants, supporting cleaner urban environments and public health.

- Energy Security & Market Resilience – Utilizing locally sourced coconut oil reduces reliance on imported fossil fuels, strengthening national energy independence.

- Economic Growth & Agricultural Support – CME production stimulates the coconut industry, creating employment opportunities and increasing revenue for local farmers.

- Operational & Engine Efficiency – CME enhances fuel lubricity, reducing engine wear and improving long-term performance.

By integrating CME into our fuel portfolio, Petron reinforces its commitment to responsible energy solutions, positioning itself as a leader in sustainable fuel innovation while delivering value to stakeholders, investors, and the communities we serve.

Driving a Cleaner Future

Our Coco Methyl Ester (CME) Roadmap

As part of our commitment to sustainable energy solutions, Petron is investing in a CME production plant, a renewable and cleaner fuel alternative derived from coconut oil. This initiative aligns with our broader decarbonization strategy, supporting national energy security, emissions reduction, and long-term business growth.

Solid Growth

According to the Climate Change Commission, the Philippines has lost 1.42 million hectares of tree cover from 2001 to 2022. Largely due to urbanization, the loss represents a 7.6% decrease in the country’s total tree cover of approximately 18.6 million hectares.

The figures are even more disheartening when it comes to forest cover. As of 2022, Philippine forestry statistics estimate that the country has lost 7.22 million hectares of forest cover, equivalent to 24% of our total land mass. This is far below the 17.8 million hectares of forest cover we reportedly had in 1934.

Reforestation has long been a cornerstone of San Miguel’s environmental stewardship efforts. Over the last two decades, our Beer, Spirits, Fuels, and Infrastructure businesses spearheaded tree and mangrove reforestation and watershed protection programs in the areas where they operate.

It was in 2019 however when San Miguel Global Power began to raise the stakes to unprecedented levels—committing to rehabilitate both upland and mangrove forests by planting seven million trees in at least seven provinces.

Six years hence, Project 747 is nearly complete, with over 6.5 million seedlings and propagules planted and grown across over 2,000 hectares in 20 provinces.

Even as we near the goal of planting 7 million trees, our efforts to expand forest and tree cover are far from done.

The numbers offer a snapshot of the project’s achievements, but do not tell the complete story. Much more has gone into the multi-year effort than simply planting trees.

To ensure high survival and success rates, SMGP structured the project into three key components. First, it worked to establish partnerships with concerned stakeholders. SMGP initiated collaboration with local offices of the Department of Environment and Resources (DENR) and local government units in targeted locations. It then sought the support of host communities and people’s organizations (PO).

Partner POs and host communities were then given proper training and designated as co-owners of the program. In all, SMGP worked with around 60 POs, including farmers’ and fisherfolks’ groups, across 20 provinces throughout the country.

The next step was to establish nurseries near the target planting sites, carefully choosing locations with sufficient access to water.

With the help from partner POs, endemic species were chosen for each site to ensure environmental compatibility. The nurseries were then managed by the POs, and these efforts successfully raised nearly 8.5 million seedlings in different locations nationwide.

Once ready, the seedlings from the nurseries were transferred to the final stage: planting. Tree species in upland areas included narra, molave, white lauan, palosapis, agoho, batino, igang, and malabayabas, while mangrove species included bakawan babae, bakawan lalaki, bungalon, and api-api.

Thanks to the ongoing collaboration among SMGP, local stakeholders, and POs—and the care given to the young trees—survival rates of planted seedlings and mangrove propagules have been high: 91% and 89%, respectively. These figures consistently exceed the DENR’s benchmark survival rate of 85%, highlighting the effectiveness of Project 747’s implementation and stewardship.

Beyond environmental restoration, Project 747 also integrated a strong livelihood component. SMGP established nine biochar facilities nationwide, operated by our partner POs, including indigenous peoples’ communities in Malita (Davao Occidental), Davao del Norte, Davao de Oro, Pampanga, Misamis Oriental, and Botolan, Zambales. These facilities produce biochar from rice hulls, which the SMGP Foundation purchases for use as organic fertilizer across Project 747 upland sites. Any excess biochar is sold by the POs to nearby farms, providing local communities with an additional income stream, while strengthening their ownership and active participation in the project.

Even as we near the goal of planting 7 million trees, our efforts to expand forest and tree cover are far from done. In March 2025, SMC, through SMGP and Petron, pledged to support the planned “5 Million Trees by 2028” program of the DENR and plant 3 million trees within the priority areas to be identified by the government.

At one million trees per year, it is a challenge as ambitious as Project 747 was at its start. The key difference today: we now have years of experience to build on and strong partnerships to help ensure long-term success.

C. Non-GHG Emissions

Non-CO2 air pollutants—including nitrogen oxides (NOx), sulfur oxides (SOx), particulate matter (PM), and carbon monoxide (CO)— are significant contributors to air quality degradation and climate impacts. Since we began reporting in 2022, San Miguel Corporation has consistently tracked these emissions in recognition of their effects on public health and the environment.

Our NOx emissions increased by 9.6% in 2024 vs 2023, driven by higher energy consumption in our Power business. In 2024, SMGP’s increase in its NOx emissions reflects growing demand from utility and industrial clients. SMGP supplies 28 % of the Luzon grid, 5% of the Visayas grid, and 9% of Mindanao grid, averaging at 22 % of the country’s total grid requirements. It is the leading power supplier in both the regulated market—serving Meralco and other distribution utilities and electric cooperatives. SMGP uses ammonia as a catalytic reagent to break down NOx emissions in exhaust flue gas into harmless nitrogen and water before they are released into the environment.

Our SOx emissions, on the other hand, increased an average of 8.9% year-over-year, driven by higher energy consumption associated with increasing economic activity. Our Power business uses a seawater flue gas desulfurization system at Masinloc Unit 3 to remove acidic and harmful substances from flue gas by using seawater’s natural alkalinity. For our Limay, Malita, and Mariveles facilities, limestone desulfurization systems are used. These processes minimize environmental impact by either neutralizing seawater before returning it to the sea or effectively removing sulfur oxides through limestone treatment. In contrast, Petron reduced its SOx emissions by 27% by continuously utilizing their 2 units of flue gas desulfurizer (FGD) and 4 sulfur recovery units (SRU). FGDs reduce SOx emissions during the fluid catalytic cracking process, while SRUs recover sulfur from refinery process streams to further reduce SOx emissions during flaring. In 2024, Petron also planted an additional 2,100 mangrove seedlings in Bataan province, strengthening its partnerships with Limay and Orion LGUs. This initiative curbs air pollution and enhances air quality by helping trap SOx and NOx and mitigate their harmful effects on human health and the environment. Furthermore, in support of SOx emissions reduction, all SMC‑SL vessels completed their transition from using industrial fuel oil, which has a sulfur content ranging from 3.5% to 0.5%, to very low sulfur fuel oil , with a sulfur content between 0.5% and 0.1%, as of December 2024. This proactive move is expected to drive a decline in SMC-SL’s SOx emissions starting in 2025.

PM emissions rose significantly in 2023 following the inclusion of two cement plants in our reporting boundary. However, our overall PM emissions decreased by 50% in 2024, driven by the continued implementation of pollution control measures across our operations to manage and control airborne particle emissions.

In particular, our Cement business has implemented mining forest programs, which aim to help reduce air pollution and mitigate the impact of its operations on air quality in surrounding communities. Notably, Northern Cement is part of the North Eastern Pangasinan Airshed (NEPA), which serves as a monitoring zone for ambient air quality and pollution levels across a defined land area where airborne particles and chemicals disperse and travel toward water bodies such as rivers, lakes, or bays. NEPA plays a key role in air quality management by promoting an integrated, area-wide approach. It enables the implementation of localized interventions, regulatory measures, and multi-stakeholder collaboration to effectively address and reduce air pollution.

Despite increased activity, our non-GHG emissions remain well within DENR and World Bank standards—reflecting strong environmental controls across our operations.

Our CO emissions have increased by 7.6% in 2024 versus 2023, primarily due to increased use of non-renewable energy – specifically natural gas—by our Power business. SMGP increased its liquefied natural gas (LNG) consumption, replacing some of the demand previously met by its coal-powered assets with gas-fired power generation units. Despite the increases in NOx, SOx and CO, these emissions remain well within DENR and World Bank emission standards.