Circular Economy

At the core of SMC’s sustainability efforts is our commitment to adopting a more circular economy model. As our operations expand, so does our demand for raw materials—making it even more critical to optimize resource efficiency, sustain our operations, and minimize waste. As a company at the forefront of nation-building, we recognize our responsibility to ensure progress must not come at the expense of the environment or the communities we serve.

We continue to strengthen our waste reduction, recycling, and recovery initiatives, while exploring innovative approaches to improve materials and waste management. These efforts help us maximize the value of the resources we use, reintroduce byproducts into production across our businesses, and minimize what ends up as waste. This stands in contrast to the traditional linear economy, where materials are used once and discarded, rather than repurposed or recovered.

A. Materials Management

In 2024, our operations used a total of 32 million MT of materials, an 18.1% increase from the previous year. This growth was primarily driven by the inclusion of San Miguel Aerocity Inc. (SMAI) in our reporting. Of the 4.4 million MT increase in nonrenewable materials, 3.9 million MT was attributed to SMAI’s land restoration activities in Bulacan for the New Manila International Airport. In addition to constructing the airport platform, these activities include biodiversity preservation efforts to align with our sustainability agenda.

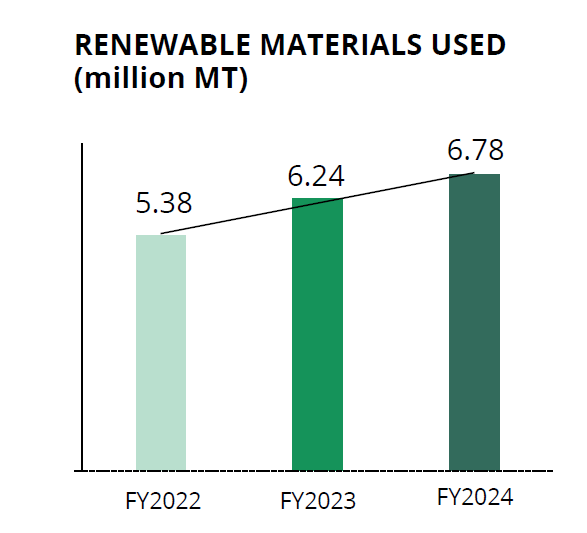

The inclusion of SMAI led to a slight decrease in the share of renewable materials, from 23.1% in 2023 to 21.2% in 2024. However, the total volume of renewable materials increased from 6.2 million to 6.8 million MT, with contributions from SMFB, Cement, SMYPC, and Petron. SMFB’s inputs–primarily agricultural commodities, glass bottles, used plastic pallets and crates-accounted for 82.5% of the Group’s renewable material usage. Additionally, Cement contributed fly ash and gypsum, SMYPC used glass cullet and plastic regrinds, and Petron provided ethanol and CME.

Recycled material use declined slightly from 3.8% to 3.1% due to a shortage of locally available glass cullet, as more of these materials were exported rather than sold domestically. Despite this, reclaimed materials played a key role as 90% of SMB’s bottles and 56% of GSM’s were reused. Spent grains and yeast from SMB, along with rendered poultry meal and pollard, were repurposed for animal feeds, representing 7.1% of the Feeds business’s renewable material use.

As our material use grows, we continue to prioritize renewable, reclaimed, and repurposed inputs that align with our sustainability agenda.

B. Solid Waste Management

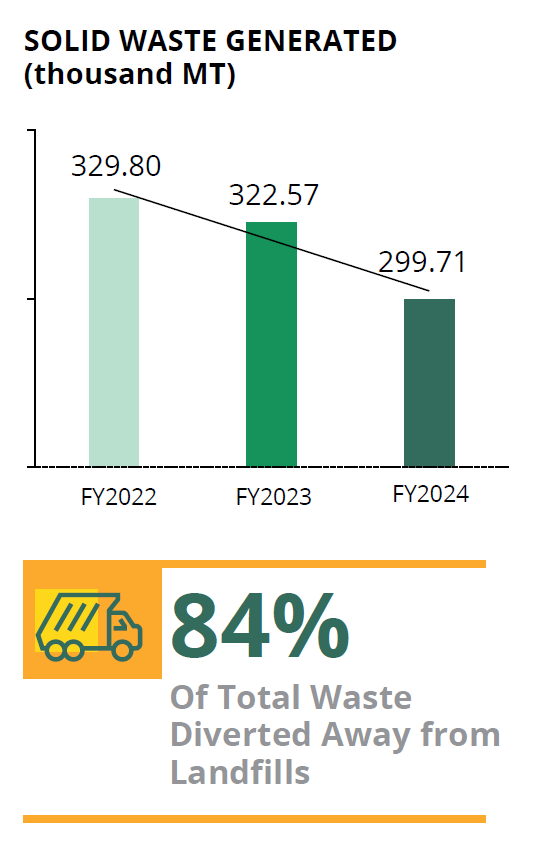

San Miguel’s steadfast compliance with the Ecological Solid Waste Management Act led to a further 7% reduction in total solid waste generated in 2024. As a national conglomerate with operations across the archipelago, SMC remains mindful of its environmental footprint and is committed to minimizing its impact by recirculating surplus materials and by-products into our operations wherever possible.

As in previous years, spent grains and yeast from our breweries comprised the largest share of solid waste at 43.2%, followed by glass cullet and jars at 26.2%. However, for both categories combined, the absolute weight declined by 11% or 36.1 thousand MT. Since these materials are reintroduced into our production ecosystem—spent grains and yeast as animal feeds ingredients, and glass cullet and jars to our glass manufacturing plants—the drop in waste generation also resulted in a corresponding decrease in waste diverted.

For plastic waste, SMC reported 26.1 thousand MT of postconsumer plastic waste in 2024, 3% lower than the previous year, covering its obliged enterprises– SMFB, Petron, and the Cement group. Of this total, 21.3 thousand MT were flexibles, while 4.8 thousand were rigid plastics. In full compliance with the EPR law, 40.5% of this volume was recovered through a combination of recycling by our Packaging business, which is now a DENR-accredited diverter, and reprocessing via Plastic Credit Exchange (PCX), from which we obtain the corresponding plastic credits.

Coal Ash Management

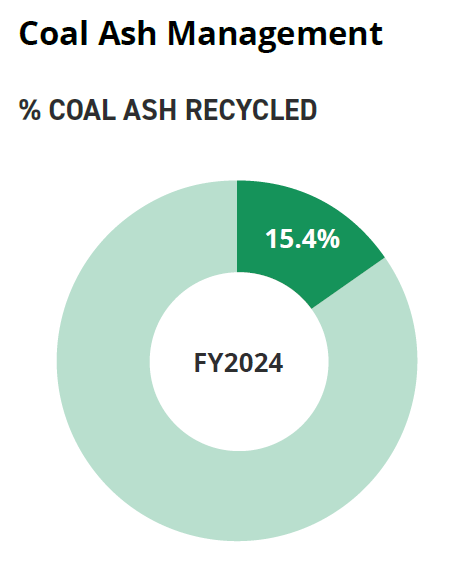

In 2024, coal ash generated by our businesses increased by 22%. This was mainly generated by SMGP’s power plants and Petron Bataan Refinery’s co-generation facility.

Of this volume, 15.4% was successfully recycled for use in our Cement businesses, where it serves as an aggregate material for cement production. The quantity is lower than prior years due to the quality of coal ash, so what could not be recycled was responsibly stored or disposed in accordance with DENR standards.

We are closing the loop on waste— repurposing byproducts like spent grain, glass, and plastics to minimize landfill impact and reinforce a circular economy.

Hazardous Waste Management

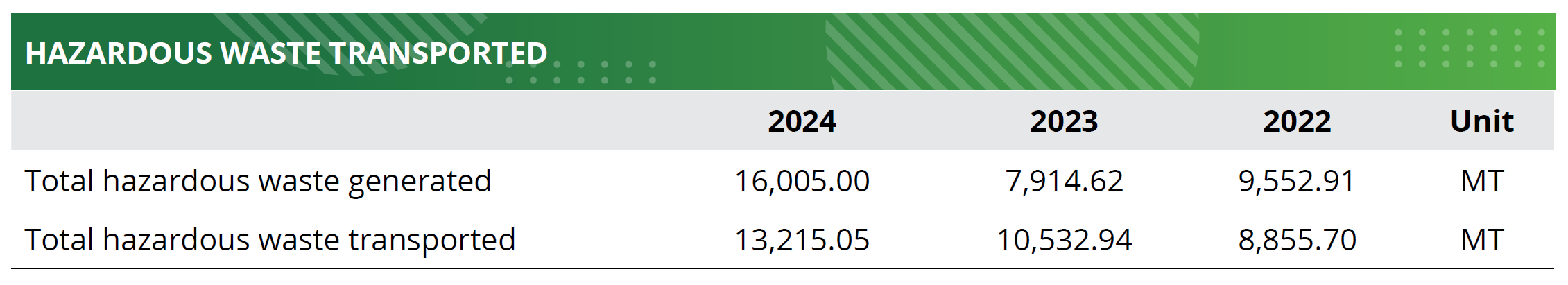

SMC generated a total of 16 thousand MT of hazardous waste in 2024, up from the previous year’s 7.9 thousand MT. Of this volume, 73% came from Petron in the form of fuel residue and sludge following their scheduled maintenance of fuel storage facilities at the Bataan Refinery. The increase in the volume of hazardous waste generated is directly attributed to this maintenance activity.

We transported 13.2 thousand MT of hazardous waste during the year, reflecting our practice of strategically storing waste until it reaches an optimal volume for safe and efficient disposal. In 2024, we diverted 41% of hazardous waste, while transporting the balance to DENR-accredited hazardous waste treaters.

Ever-cognizant of the risks involved in hazardous waste management, SMC ensures that all hazardous materials generated from our operations are collected, transported, and disposed of responsibly and in a timely manner, in full compliance with regulatory standards.